what is oil type sorento use ?

Is it safe to use synthetic on new sorento ?

Is it safe to use synthetic on new sorento ?

And here's another one:The ASTM tests and OEM engine tests that are used in creating specifications (for example) Dexos1 are REAL tests. And they are much more complex, are better focused on real world problems, and have better reproducibility and repeatability than RAT's "squeaky wheel" rig. I know, because I've used those "film strength" test machines myself and I have also stood over engine tests as they are being performed...

To completely dismiss a multi-billion dollar industry and declare it trumped by a guy with one heavily debunked test is insulting to those of us who spend our lives in the industry and a very stupid way to make decisions about your investment of a vehicle... I don't agree with using the "RAT ranking"...

OEMs are generally more interested in fired engine tests than bench test results. Bench tests are good qualifiers when first investigating new chemistry, but in engine oils nothing beats running the oil in an actual engine, tearing it down and looking at the results.

During these tests the engines are also rigged up to a maze of sensors which identify loads, operating temperatures, internal pressures, cycling of the engine and periodic oil analysis... All this data combined together can be used to determine a pass or fail.

And here's one from a Certified Lubrication Specialist:I would like to begin by stating unequivocally that the test utilized for comparison of the different motor oils is NOT an industry accepted test and has not been peer reviewed or validated by any certification body such as American Society for Testing and Materials (ASTM), American Petroleum Institute (API) or the American Chemistry Council (ACC). Therefore, I do not consider the test data valid. I should note that non-ASTM associated bench tests are not the most reliable indicators of field performance.

Additionally, I think the primary concern I had with the information is that one cannot effectively measure “load carrying capacity/film strength” in a 30 second test that is NOT considered a standard industry test with the rigorous inter-laboratory round robin studies needed to generate the measurement system precision statements. The gold standard to evaluate the different lubricants would be controlled engine testing... It is my opinion that a 30-second test is not a proper performance test of the load-carrying capacity of a lubricant in boundary lubrication regimes.

And here's another one:I appreciate this guys desire to tell the truth, but his test method is completely wrong. Motor oils are formulated to run in actual motors. Not on bearing testers.

The testing done here is only one part of a product evaluation. This is really the problem here, 540 thinks that a pass in the beginning testing format is the end to all, it is not.

We have seen oils look great in a bench test and totally fail in the real world in a running engine... even with some oils that have good shear qualities have an 'etching problem' that only shows up after miles of use that would never show up in 540 Rat's test... 540 Rat's testing is a long ways from being complete or useful in making any determination what or who's oil may be better in use...

oh ya, I [Manuel Azevedo] worked for Oronite Additives in the engine lab for over twenty years, so I have seen a lot. By the way, Oronite is Chevron Corp's additive company and sells worldwide to many other oil companies...

Sorry 540, but your testing has nothing to do with an engine!!! An engine produces all kinds of different acids and particulate matter. So how an oil/additive package holds up and reacts to these contaminates is going to be different, in a lot of cases, than what your so called "holy grail of oil testing" rig indicates.

You are only doing the first stages of an oil test. What you are doing is what is done to qualify an oil to move on to more real-world testing, but you seem to think a bench test is all there is in any kind of test, just shows you haven't got a clue how any of your tested oils will work in an engine for the duration of an oil change interval... Your testing means nothing to an engine and an engine is what the oil is designed for, so what good exactly is this testing for an engine oil if your testing has nothing to do with an engine???

Oh well for as long as you have been trying to show you know more than anyone else in the business than anything said here is beyond your ability to understand what is going on.

You can rest assure that using synthetic oil is the best thing you can use on your vehicle. I've been using synthetic oil before it was available to the public and since then I have never used anything else. Back in 1991, I bought a brand new 1992 Ford F 150 and I put 485,000 miles on it when I sold it. I never had to do any interior work on the engine. Used to change the oil once a year, that was it. Used to be my daily driver and used to put 120 miles a day, to go back and forth from work.I plan on using Royal Purple 5w-30 for my first oil change after buying the car at 60k miles on it. I assume the previous owner(s) used conventional oil.

My 2010 Kia Soul I bought new only saw Royal Purple 5w-20 in it and never had one issue with lubrication for 130k miles. I was doing 7500 mile oil changes to keep the warranty but after it hit 100k, I was extending it to 10k, sometimes 12k miles between changes. The oil coming out looked just as good as the oil going in.

You can rest assure that using synthetic oil is the best thing you can use on your vehicle. I've been using synthetic oil before it was available to the public and since then I have never used anything else. Back in 1991, I bought a brand new 1992 Ford F 150 and I put 485,000 miles on it when I sold it. I never had to do any interior work on the engine. Used to change the oil once a year, that was it. Used to be my daily driver and used to put 120 miles a day, to go back and forth from work.

Now that I have my new Sorrento, after my free oil change that I am going to get from the dealer for the nest three years, I will definitely will go to synthetic.

Most discussions about oil are based on religion.

Oil is oil. Just read the car book and apply with reason instead..

That AAA PDF is very detailed and telling. I am going to officially base-line my car just in case the dealership didn't use synthtic when they changed it last...they have a sticker on the window but it only says 5W-30 and nothing about oil type. Thanks for all of this great information!The American Automobile Association (AAA) is one of the most recent company to promote the benefits of using synthetics. The popular club recently conducted in-depth testing to determine if it’s worth paying more for synthetic oil over conventional oil.

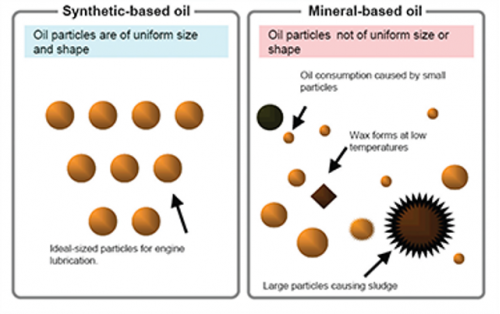

"Oil protects critical engine components from damage and AAA found that synthetic engine oils performed an average of 47 percent better than conventional oils in a variety of industry-standard tests," said John Nielsen, AAA’s managing director of Automotive Engineering and Repair.

"With its superior resistance to deterioration, AAA’s findings indicate that synthetic oil is particularly beneficial to newer vehicles with turbo-charged engines and for vehicles that frequently drive in stop-and-go traffic, tow heavy loads or operate in extreme hot or cold conditions."

AAA’s research included eight industry-standard ASTM tests focusing on 'shear stability', 'deposit formation', 'volatility', 'cold-temperature pumpability', 'oxidation resistance' and 'oxidation-induced rheological changes'. Each test was performed on five synthetic and five conventional oils.

The results were published in May 2017:

AAA Engine Oil ResearchReport (PDF)

Pretender

That AAA PDF is very detailed and telling. I am going to officially base-line my car just in case the dealership didn't use synthtic when they changed it last...they have a sticker on the window but it only says 5W-30 and nothing about oil type. Thanks for all of this great information!